Capabilities

Rubber Molding

Molding rubber is our specialty, and we have the ability to assist with parts design, prototyping, production, finishing, and assembly, so you don’t have to work with multiple companies–JRW is your one stop resource for all your rubber molding needs.

Transfer Molding

Transfer molding is best suited to low to medium volume production of small to medium sized parts. It is a flexible solution offering the ability to produce intricate-shaped products and allows for the addition of colored and translucent compounds.

Liquid Silicone Molding

The process for molding Liquid Silicone Rubber (LSR) is suitable for relatively small parts with high annual volume needs. This material allows for very short cycle times which makes it an ideal candidate for two-shot molding with plastic material.

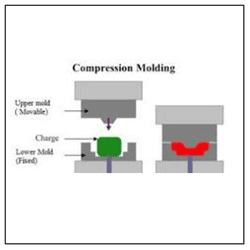

Compression Molding

Compression molding is best suited to low production volumes of medium to large size parts that use higher cost materials. Compression molding is viewed as being labor intensive, but this can be addressed through automation to a point where it matches the efficiency of injection molding.

Rubber to Metal Bonding

Gluing metal to rubber is a secondary, manual process for joining rubber to a metal insert. It is a good solution in specific situations where bonding is not possible either for cost or practical considerations.

Prototyping

At Jefferson Rubber, we offer customized solutions depending on the product specifications using either 3D printed elastomer parts, prototype tooling with a limited number of parts or limited tooling cavitation for initial process set-up and validation.